About Us

OUR SERVICES

Manufacturing Facilities :

APG Moulding Machines

Mascasts is equipped with Specially designed Advanced Pressure Gelation (APG) casting machine for manufacturing Epoxy Casted Components. Precisely made Dies and Moulds enhance the quality of epoxy casted insulators and components. We manufacture all kind of epoxy insulators which are as per our standards and also manufactures the custome designs pertains to vairous OEM's as per their design.

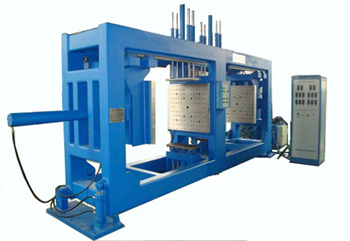

DMC Moulding Press Machines

We utilise best of Hydraulic Press machines for manufacturing Dough Moulded Components (DMC) as well as Sheet Moulded Components. We have small to large capacity hydraulic presses to cater all sized DMC/ SMC moulded comonents. Those advanced presses provide best quality DMC porducts which withstands all designed torque loads and physical stresses compiling to its electrical insulation properties.

Quality Testing Facility :

We Are ISO 9001 - 2008 Certified Company.

After manufactung insulators it is necessary to test its perforamce for Electrical and mechanical and Design specifications.

High Voltage Flash Over Test Rig

As per british standards all manufatured insulators are tested for flash over test.

- first the insulators are mounted on test panel of rig

- then all insersts of insulaors are connected to variable voltage frequency source

- then its gradually supplied with designed value of voltage power

- this power is being hold for 1 min time , in test time there must not be any flash or voltage puncher happen.

Causes of failure of epoxy insulators :

- crack in insulator body

- porosity in casting or blow holes

- imurities in epoxy materials

Partial Discharge Measurement Rig

Small sparks that happens inside of epoxy insulators body section which creates fine porosity and loosen material molecules results in insulator failure. This happens due to erosion of epoxy material.

Universal Testing Machine

Insulators are tested for its designed Bending stress, Cantilever Test, And Tensile Stress etc.

Machine is loaded with computerised logger and all tests recorded.

All other Visual, Dimensional, Hydro etc. tests are done as per apporved QAP and all records are maintained for Reverse Tracibility.